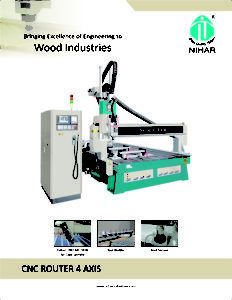

CNC Router 4 Axis Machine

Techincal Specification of Panel Dividing Saw Machine

| Description | CNC ROUTER 4 AXIS |

|---|---|

| XYZ Working Area | 1830mm*3040mm*500mm |

| Process Precision | ±0.05mm |

| Reposition Precision | ±0.025mm |

| XY Structure | High Precision Planetary Gear Box X and Y Movement. |

| Z Structure | Backless Free Taiwan TBI Ball Screw, Taiwan Square Linear Guide. |

| Spindle | Italian HSD 9KW ATC air cool spindle. (spindle can rotation 0-180’c freely) |

| Spindle Speed | 0-24000 RPM |

| Tool Magzine | Linear tool library 8 tools |

| Tool Holder | 8 pcs |

| Table | Vacuum suction worktable 8 Zones |

| Motor and Driver | Japanese Yaskawa Servo motor and Driver |

| Motoreducer | Japanese SHIMPO |

| Inverter | Taiwan Delta Inverter 11kw |

| Control System | Taiwan Syntec control system |

| Software | Artcam, Mastercam, UG, Powermill |

| Command | G code (HPGL,U00,mmg,plt) |

| Collet | Er32 |

| Max.Idling Speed | 60m/min |

| Max.Working Speed | 35m/min |

| Oil Injection | Manual |

| Cable | Germany Igus cable |

| Working Voltage | AC380V- Three Phase |

Silent Features

- Nanxing has invested hundreds of millions for taking in 500 world best CNC and robot machines for metal works, making its production ranked No. 1 in thewoodworking machinery industry. SOP professional assemble lines.

- Powerful SYNTECH CNC CONTROL SYSTEM equipped with specialist software to runfor high process efficiency and easy operation, the fastest in the field.

- Adapt 7 kinds of file format and common furniture design software.

- Customer Reference: 30+ countries; 2000+ machines

Applications of Woodworking Panel Dividing Saw Machine

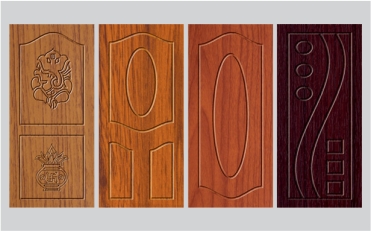

- Materials like wood, gypsum, foam and wax can be worked upon to create molds It is possible to create decoration elements with these machines and work on acrylic, MDF, artificial stone, PVC, plastic and soft metals like aluminum and copper

- Different types of furniture items such as wooden doors, plates, tables, cabinets, windows, chairs and office furniture can be created with these machines.

- Some of the other items that can be created with these machines include game cabinets, voice boxes, sewing machine tables and computer tables

Frequently Asked Questions

There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat.

There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat. There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat.

There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat. There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat.

There are many variations of passages the majority have suffered alteration in some fo injected humour. Lorem ipsum dolor sit amet, consectetur adipiscing elit Ut sunt in culpa qui officia deserunt mollit anim id est laborum. Excepteur sint occaecat cupidatat.For Business:

Request a call back

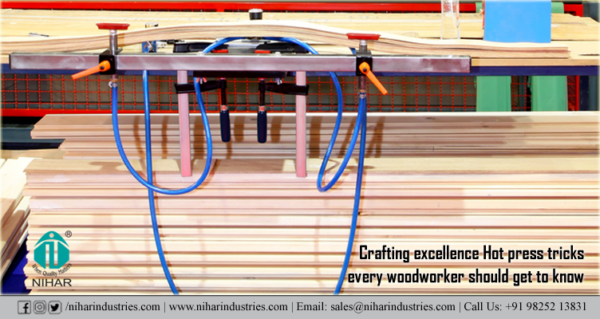

“ The cold press machine offered by Nihar Industries brings a lot of flexibility when it comes to the thermal pressing technique. This naturally makes it easier to derive a wider scale of positive results..”

Ankit Munka

“The Hot press & Roller press systems crafted by Nihar Industries are quite easy to use and can produce fast results. This certainly blends well with my needs for producing more number of finished units in a given timeframe.”

Dinesh Patel

“ The various features offered by the cold press machine designed by Nihar Industries makes it easier for me to customize my production according to my needs. This makes them extremely user friendly and resource saving.”

D. K. Patel

“ The cold press machines developed by Nihar Industries are quite easy to use and they can offer reliable services for both wooden and non-wood materials.”

Jitu Patel

“ I often need to work with thick wooden surfaces which require some heavy pressing. The vacuum presses crafted by Nihar Industries have time and again provided me with the results that I want.”

Rakesh Bhagat

“ This panel saw machine is not only budget-friendly but they are also high on production rates. Such benefits have greatly helped me to take my business to higher levels of success.”