Woodworking is a progression that requires the correct blend of skill, precision, and paraphernalia to yield superlative results. You must select the best apparatuses to qualify your production process whether you’re an expert carpenter who has a store or maintains a major woodworking brand. This will help you develop the finest quality finished goods and increase ROI margins.

You can invest in top-grade woodworking machineries as they come with wide range of options. Your choice and needs matter when you are looking to streamline your efficiency. Some of the most extensively used woodworking machines include. Let’s look closely at these machines and see what they can do.

CNC Router Machine

A CNC router machine or Computer Numerical Control router machine is a means that has meaningfully transformed the woodworking industry over the years. It ensures high-precision cutting and is a great device for automation and complex cuts that would be very thought-provoking to accomplish manually. The primary advantages of using a CNC router machine comprises the following:

- Reproducing the same products: Once programmed, the CNC router can reproduce the same design several times with complete consistency.

- Precision Cutting: CNC routers follow programmed designs with amazing meticulousness. Hence, making them a unified choice for extensive, intricate, complex patterns, and engravings.

- Efficiency: These machines automate the cutting process, thus expressively plummeting production time and enhancing productivity.

- Versatility: CNC routers are perfect for processing and working with varied materials type, such as wood, MDF, plastic, and soft metals.

Vacuum Press Machine

Veneer lamination and woodworking projects require seamless adhesion. The vacuum press machine is a tool that does that. This machine uses the mechanism of vacuum pressure to press the veneers onto substrates, thus confirming a smooth finish. The main benefits of using this machine are:

- Uniform Adhesion: The vacuum press prevents the formation of air pockets and evenly distributes pressure guaranteeing a flawless bond.

- First-rate Finish: It produces professional-grade consequences indispensable for high-end woodworking projects.

- Improved Effectiveness: It speeds up the lamination process significantly, delivering faster results than traditional manual pressing techniques.

- Flexibility: The machine is suitable for abundant applications, including the production of custom furniture designs and curved surfaces.

Cold Press Machine

The cold press machines are used for gluing solid wood boards and large panels. Unlike the hot press machines, they operate at room temperature and only use pressure to bond the materials. These machines offer the following advantages:

- Consistent pressure: They offer even bonding results without the potential of overheating or warping the materials.

- Energy efficiency: As they do not involve heat, cold press machines consume less energy.

- Perfect for materials of delicate nature: They are well-suited for materials sensitive to heat, like natural wood veneers.

- Reliable performance: They can produce sturdy and enduring pledges that progress the strength of the wooden structures.

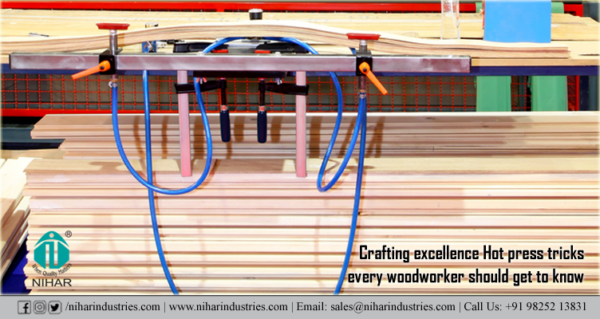

Hot Press Machine

Hot press machines are apt for undertakings that require fast and strong bonding. They use heat and pressure to activate the adhesives, ensuing in quicker curing times. Here are the advantages of using hot press machines.

- Faster production: Curtails the waiting time for the glue to dry, thereby improving efficiency.

- Robust bonding: The combination of heat and pressure results in exceptionally durable adhesion.

- Enhanced surface finish: It augments the quality of the laminated panels reducing faults.

These machineries offer a wide range of benefits for a woodworking production facility, thus ensuring that they grow a business’s profit margin. Hence, you can deliberate investing in them for your woodworking production needs.