CNC 6-Sided Drilling Machine

Techincal Specification of Panel Dividing Saw Machine

| Description | NCB 612 | NCB 612S | NCB 612DXT | |

|---|---|---|---|---|

| Total Power | 18.03KW | 19.75KW | 23.93 KW | |

| Machine Size | 6,150*2,273*2,325 mm | 6,150*2,273*2,325 mm | 6,150*2,806*2,325 mm | |

| Power Supply | 415V/50Hz | 415V/50Hz | 415V/50Hz | |

| Air Supply | 0.6-0.7 MPa | 0.6-0.7 MPa | 0.6-0.7 MPa | |

| Total Weight | 3,200 Kg. | 3,200 Kg. | 3,850 Kg. | |

| Controlsystem | Brand | SYNTEC | SYNTEC | SYNTEC |

| Panel Size | Length | 200-3,000 mm | 200-3,000 mm | 200-3,000 mm |

| Width | 30-1,200 mm | 30-1,200 mm (Sawblade:30-1100) | 30-1,200 mm | |

| Thickness | 10-60 mm | 10-60 mm | 10-60 mm | |

| Max. Traveling | (X/U) Axis | 135 m/min | 135 m/min | 135 m/min |

| Yaxis | 75 m/min | 75 m/min | 75 m/min | |

| Zaxis | 30 m/min | 30 m/min | 30 m/min | |

| Transmission Mode | X Axis | Rack and Pinion | Rack and Pinion | Rack and Pinion |

| Y Axis | Rack and Pinion | Rack and Pinion | Rack and Pinion | |

| Z Axis | Ball Screw | Ball Screw | Ball Screw | |

| Working Table | Material | HPL+Steel | HPL+Steel | HPL+Steel |

| Table Size | 2,150 x 600 | 2,150 x 600 | 2,150 x 600 | |

| Height | 960 mm | 960 mm | 960 mm | |

| Drilling Block | Drilling Block Qty | Top1; Bottom 1 | Top1; Bottom 1 | Top1; Bottom 1 |

| Vert. Drillsqty(top) | 18 | 18 | 18*2 | |

| Horiz. Drillsqty(top) | X:6+Y:4 | X:6+Y:4 | X:6×2 +Y:4×2 | |

| Vert. Drillsqty(Bottom) | 9 | 9 | 9 | |

| Max Drill Diameter | 35 mm | 35 mm | 35 mm | |

| Drillspacing | 32 mm | 32 mm | 32 mm | |

| Rotationspeed | 5000 RPM | 5000 RPM | 5000 RPM | |

| Shankdiameter | 10 mm | 10 mm | 10 mm | |

| Saw Blade | Power | – | 1.7kw | – |

| Size | – | 100*22*64 | – | |

| Processing Range | – | 50-1200 mm | – | |

| Main Spindle | QTY | Top1 Bottom 1 | Top1 Bottom 1 | Top1 Bottom 1 |

| Power | 3.5 kw x 2 | 3.5 kw x 2 | 5.5 Kw*1, 3.5 Kw*1 | |

| Dust Collector | QTY | 2 | 2 | – |

| Diameter | Top 200 mmx1 Lower 125 mmx1 | Top 150 mmx1 Lower 125 mmx1 | Top 200 mmx1 Lower 125 mmx1 | |

| Speed | >28m/min | >28m/min | >28m/min | |

*Specifications are subjected to change without notice.

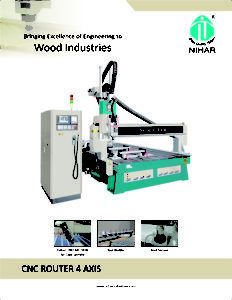

Silent Features

- Nanxing has invested hundreds of millions for taking in 500 world best CNC and robot machines for metal works, making its production ranked No. 1 in thewoodworking machinery industry. SOP professional assemble lines.

- Powerful SYNTECH CNC CONTROL SYSTEM equipped with specialist software to runfor high process efficiency and easy operation, the fastest in the field.

- Adapt 7 kinds of file format and common furniture design software.

- Customer Reference: 30+ countries; 2000+ machines

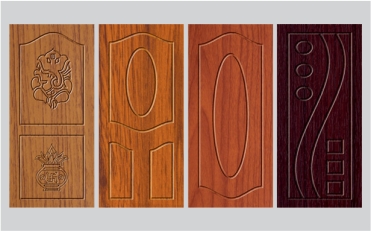

Applications of Woodworking CNC 6-Sided Drilling Machine

- Materials like wood, gypsum, foam and wax can be worked upon to create molds It is possible to create decoration elements with these machines and work on acrylic, MDF, artificial stone, PVC, plastic and soft metals like aluminum and copper

- Different types of furniture items such as wooden doors, plates, tables, cabinets, windows, chairs and office furniture can be created with these machines.

- Some of the other items that can be created with these machines include game cabinets, voice boxes, sewing machine tables and computer tables