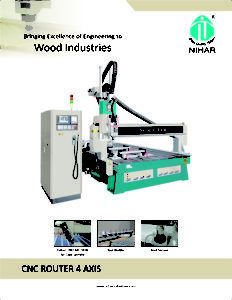

CNC Router 4 Axis Machine

Nihar Industries is the proud manufacturer of CNC Router 4 Axis Machines that ensures excellent performance for a wide range of operations. We offer high grade CNC Router 4 Axis Machines that are equipped with superior electronics and working beds. Our experts have created these machines with the help of the finest raw materials. We have also adhered to the current industry standards and the best practices so that our customers can greatly benefit from these machines. Our products are made in keeping with the best industry practices which mean that a very high level of accuracy can be maintained with every operation. The CNC feature of these machines helps to customize all projects smoothly while at the same time maintain superior accuracy.

The machines can also deliver excellent performance each and every time along with smooth operation for the working personnel. Our CNC Router 4 Axis Machines can be used for effectively processing materials that have uneven and rough surfaces. They can also be used for materials having unusual shapes and structures. You can also use our CNC Router 4 Axis Machines for cutting bevel engraving and milling. These machines maintain a high level of accuracy at every step of the way and can work well even for extremely complex tasks.

Techincal Specification of Panel Dividing Saw Machine

| Description | CNC ROUTER 4 AXIS |

|---|---|

| XYZ Working Area | 1830mm*3040mm*500mm |

| Process Precision | ±0.05mm |

| Reposition Precision | ±0.025mm |

| XY Structure | High Precision Planetary Gear Box X and Y Movement. |

| Z Structure | Backless Free Taiwan TBI Ball Screw, Taiwan Square Linear Guide. |

| Spindle | Italian HSD 9KW ATC air cool spindle. (spindle can rotation 0-180’c freely) |

| Spindle Speed | 0-24000 RPM |

| Tool Magzine | Linear tool library 8 tools |

| Tool Holder | 8 pcs |

| Table | Vacuum suction worktable 8 Zones |

| Motor and Driver | Japanese Yaskawa Servo motor and Driver |

| Motoreducer | Japanese SHIMPO |

| Inverter | Taiwan Delta Inverter 11kw |

| Control System | Taiwan Syntec control system |

| Software | Artcam, Mastercam, UG, Powermill |

| Command | G code (HPGL,U00,mmg,plt) |

| Collet | Er32 |

| Max.Idling Speed | 60m/min |

| Max.Working Speed | 35m/min |

| Oil Injection | Manual |

| Cable | Germany Igus cable |

| Working Voltage | AC380V- Three Phase |

Silent Features

- 4-Axis Control – Enables complex 3D carving, engraving, and contouring.

- High Precision – Advanced stepper/servo motors ensure accuracy and smooth operation.

- Rigid Structure – Heavy-duty frame for vibration-free performance.

- Automatic Tool Changer (Optional) – Reduces downtime and boosts efficiency.

- Rotary Axis Capability – Ideal for cylindrical and intricate 3D work.

- Advanced Spindle System – High-speed spindle for superior cutting performance.

- User-Friendly Controller – Easy-to-use interface with high-speed data processing.

- Material Versatility – Works with wood, acrylic, MDF, PVC, aluminum, and more.

- Vacuum Table (Optional) – Strong holding power for stable machining.

- Dust Collection System – Keeps the workspace clean and enhances safety.

Applications of Woodworking Panel Dividing Saw Machine

- Materials like wood, gypsum, foam and wax can be worked upon to create molds It is possible to create decoration elements with these machines and work on acrylic, MDF, artificial stone, PVC, plastic and soft metals like aluminum and copper

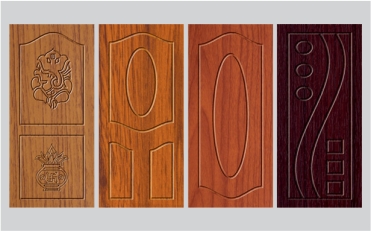

- Different types of furniture items such as wooden doors, plates, tables, cabinets, windows, chairs and office furniture can be created with these machines.

- Some of the other items that can be created with these machines include game cabinets, voice boxes, sewing machine tables and computer tables