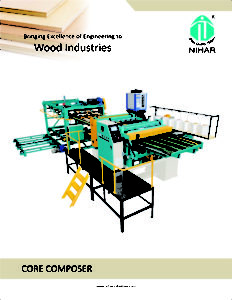

Core Composer Machine

Techincal Specification of Core Composer Machine

| Description | CORE COMPOSER |

|---|---|

| Jointing Machine Length | 3600mm |

| Jointing Machine Height | 2500mm |

| Jointing Machine Width | 2600mm |

| Stacker Machine Length | 4000mm |

| Stacker Machine Height | 2500mm |

| Stacker Machine Width | 2200mm |

| Drives and Motors | Servo (Siemens Make) |

| Controls | By PLC “SCHNEIDER” |

| Transmission Speed | 0-35m/Minutes (Adjustable) |

| Working Efficiency | 300 Pcs/hr |

| Input Power | 3Phase, 380V, 50Hz |

| Front Driver | 3.5KW Siemens (German) Servo Motor |

| Rear Driver | 3.5KW Siemens (German) Servo Motor |

| Edge Cutter Driver | Motor+ CHAIN TAIL Taiwan |

| Total Power Required | 16.5KW |

| Front and Rear Drive Reducer | Yes |

| Rotary Actuator | Festo Germany |

| Automatic Core Veneer Corrector | Yes |

| Water Cooling Air Condition | Yes |

| Electric Lateral Platform | Yes |

| 4*4 – 4*8 Electric Conversion | Yes |

| Elevator Platform | Yes |

| Speed Controls | Yes |

| Finished Panel Counter | Yes |

| L X W X H | 12000 mm x 2600 mm x 2500 mm |

| Structure | Steel Plate Structure |

| Total Weight | 7000Kg |

*Specifications are subjected to change without notice.

Applications of Woodworking Core Composer Machine

Each and every New CNC Router with Rotary Attachment Machine that is designed and crafted by Nihar Industries has been tested to deliver high precision results for diverse projects. The machines can also be customized fully to produce target specific results.

- Membrane Doors

- Wood Carving

- 3D Engraving