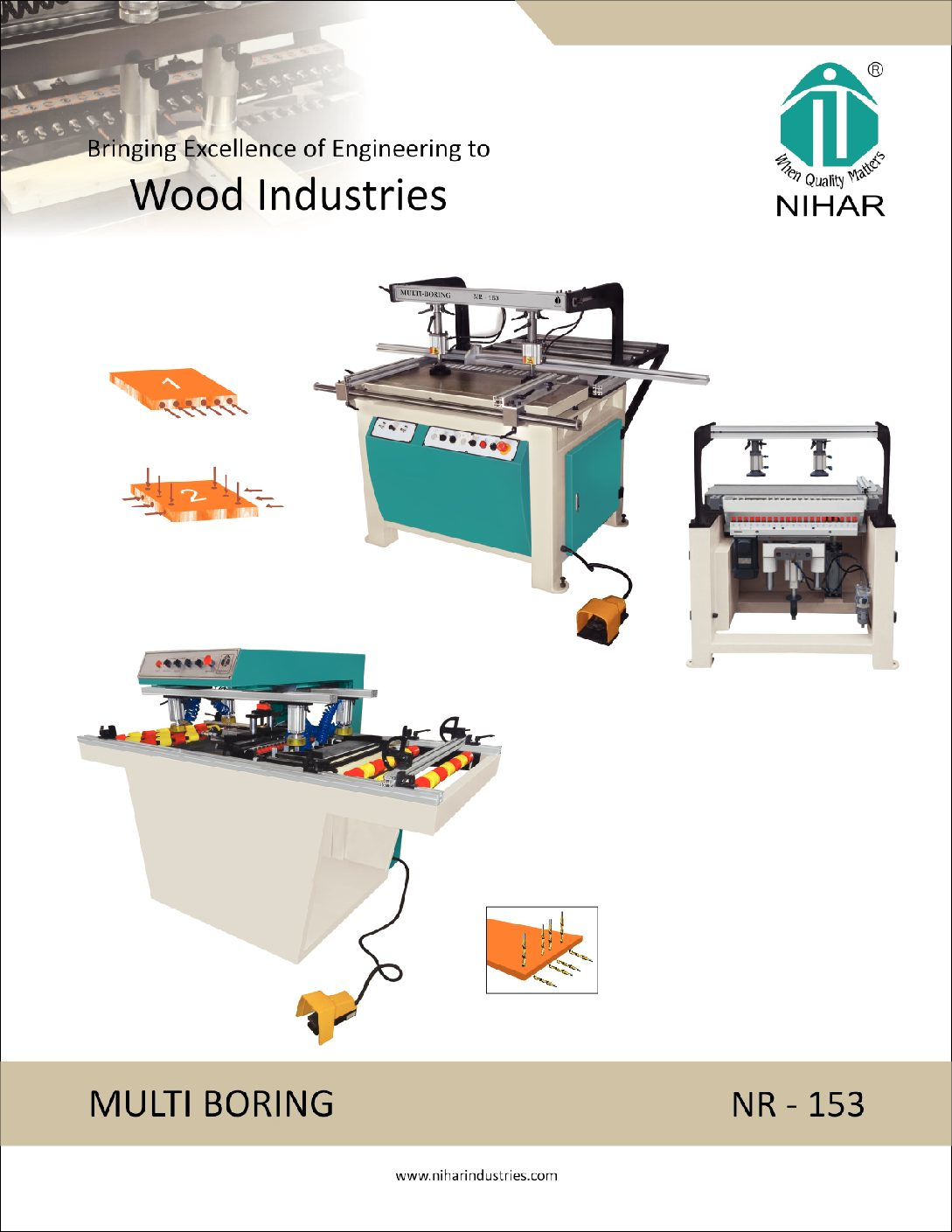

Multi Boring Single Raw Machine

Nihar Industries is one of the most reliable producers of top end multi boring single raw machines in India. The Multi Boring machines offered by Nihar Industries can come in the form of single raw and double raw models. These machines offer a number of practical advantages that make them perfect for any kind of wood boring project. These include quick and easy changing of drills, locking system of the spindle shaft, pneumatic clamping arrangement as well as application of anti wear materials meant for the sliding parts.

These machines are also equipped with heavy duty and rigid frames that can be used for holding the boring heads. The drilling depths that can be achieved by these Woodworking Multi Boring machines are 640 mm. The total number of spindles included in a single set is 21 and the spindle rotation speed that can be achieved by them is 2800 RPM. Such features make them ideal for heavy boring activities.

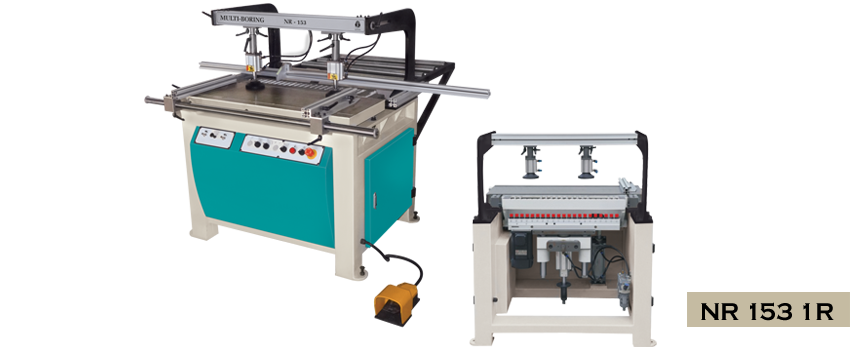

Techincal Specification of Multi Boring Single Raw Machine

| Description | NR 153 1R |

|---|---|

| Maximum thickness | 80mm |

| Maximum Size of Job | 2000mm X 640mm |

| Number of Spindle Head | 1 Nos |

| Number of Spindles in One Head | 21 Nos |

| Total Spindles | 21 Nos (21 x 1) |

| Center Distance Between Each Spindle | 32mm |

| Center Distance Between First & Last Spindle | 640mm |

| Minimum Centre Distance Between Two Vertical Head | – |

| Maximum Centre Distance Between Two Vertical Head | – |

| Shank diameter of drill | 10mm |

| Spindle Rotation Speed | 2800RPM |

| Maximum Drilling Diameter | 32mm |

| Drilling Depth | 0-50mm |

| Compressed Air Requirement | 6-8 kg/cm2 |

| Total Power | 1.5KW / 415V /50 Hz |

*Specifications are subjected to change without notice.

Applications of Woodworking Multi Boring Single Raw Machine

Powerfully designed Multi Boring Single Raw Machines offered by Nihar Industries can deliver a robust performance each and every time and can offer a range of practical advantages that make them highly suitable for processing functions.

- Panel Drilling

- Ply Drilling

- Lock Drilling